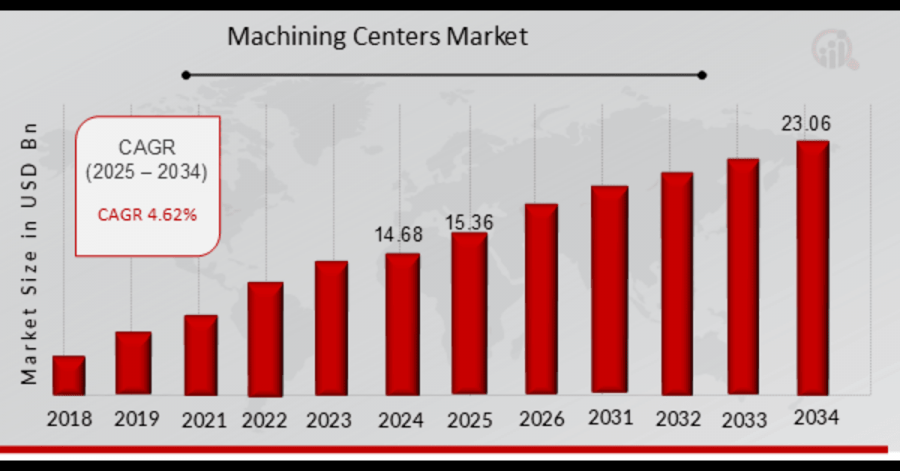

Machining Centers Market Growth to 23.06 USD Billion by 2034, Driven by 4.62% CAGR During 2025-2034

The Machining Centers Market focuses on advanced equipment for precision manufacturing across industries.

CALIFORNIA, CA, UNITED STATES, January 22, 2025 /EINPresswire.com/ -- Market Research Future published a report titled, the Machining Centers Market Size, Share, Competitive Landscape and Trend Analysis Report, by Product Type, Control System, Spindle Type, Application, Regional: Global Opportunity Analysis and Industry Forecast till 2034. the Machining Centers Market Size was estimated at 14.68 USD Billion in 2024. The Machining Centers Market Industry is expected to grow from 15.36 USD Billion in 2025 to 23.06 USD Billion till 2034, at a CAGR is expected to be around 4.62% during the forecast period 2025 - 2034.

Machining Centers Market Overview:

The machining centers market is experiencing significant growth, driven by the increasing demand for precision machining in various industries, including automotive, aerospace, and electronics. Machining centers are automated devices that combine multiple machining functions, such as drilling, milling, and turning, into a single integrated system. These centers are widely used in manufacturing to improve productivity, reduce human errors, and ensure precise and consistent results. Their ability to perform complex machining tasks efficiently and accurately has made them a preferred choice in modern manufacturing facilities.

The machining centers market is poised for expansion as manufacturers increasingly adopt automation solutions to streamline production processes. With technological advancements in robotics, Artificial Intelligence (AI), and Industry 4.0, machining centers are evolving to deliver higher performance, flexibility, and connectivity.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/23044

Key Companies in the Machining Centers Market Include

Yamazaki Mazak

Fadal

NakamuraTome

Sodick

Hurco

Bridgeport Machines

Okuma

Mazak

Makino

Haas Automation

Doosan Machine Tools

Charmilles Technologies

DMG Mori

Market Trends and Highlights:

One of the key trends in the machining centers market is the growing demand for vertical machining centers (VMCs). Vertical machining centers are known for their compact design, which makes them ideal for smaller shops and facilities that require high precision. VMCs are highly versatile and can handle complex machining operations with ease, which has led to their increasing popularity, particularly in industries such as automotive and electronics.

In addition, there is a rising demand for five-axis machining centers. These machines, which can move the tool or the workpiece along five axes simultaneously, offer enhanced precision and versatility compared to traditional three-axis machines. The increasing need for precision in sectors like aerospace, defense, and medical device manufacturing is a key driver behind this trend.

Market Dynamics:

The dynamics of the machining centers market are influenced by several factors, including technological advancements, industry-specific demands, and economic conditions. The increasing demand for precision manufacturing and the need to optimize production efficiency are two critical drivers in the market. In addition, the rise of smart manufacturing and the integration of IoT in machining centers are creating new opportunities for growth in the industry.

Furthermore, the need for cost-effective solutions that can improve productivity and reduce operational costs is compelling manufacturers to invest in advanced machining center technology. The ongoing push for higher production rates, better quality control, and shorter lead times is shaping the future of the machining centers market. Manufacturers are increasingly seeking ways to implement automated solutions that can handle high-volume production with minimal manual intervention.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=23044

Market Drivers:

Demand for Precision and Efficiency: Industries such as automotive, aerospace, and electronics require high precision in their manufacturing processes. Machining centers provide the necessary accuracy and consistency to meet these demands, driving their widespread adoption.

Technological Advancements: The introduction of advanced technologies, such as AI, robotics, and IoT, is enhancing the capabilities of machining centers. These innovations help improve production efficiency, reduce downtime, and enable manufacturers to stay competitive in a rapidly evolving market.

Automation and Industry 4.0: The increasing adoption of automation in manufacturing is a key driver for the machining centers market. Industry 4.0 solutions, such as smart factories and connected systems, are making it easier for manufacturers to monitor and control machining processes, leading to enhanced productivity and cost efficiency.

Market Restraints:

Despite the positive growth prospects, several challenges could limit the expansion of the machining centers market:

High Initial Investment: The cost of purchasing and setting up machining centers can be prohibitively high, especially for small and medium-sized enterprises (SMEs). The capital investment required for these machines, coupled with the cost of maintenance and training, can limit their adoption, especially in developing regions.

Complexity and Skilled Labor Shortage: While machining centers provide numerous benefits, their complexity requires skilled operators who can manage the machines effectively. The shortage of skilled labor in some regions can be a significant barrier to the widespread adoption of advanced machining technologies.

Browse In-depth Market Research Report on Machining Centers Market: https://www.marketresearchfuture.com/reports/machining-centers-market-23044

Machining Centers Market Segmentation:

The machining centers market can be segmented based on product type, application, and region:

By Product Type:

Vertical Machining Centers (VMC): These machines are widely used due to their ability to perform multiple tasks in a compact space.

Horizontal Machining Centers (HMC): Horizontal machining centers are primarily used for heavy-duty operations and large-scale production.

Five-Axis Machining Centers: These machines offer higher flexibility and precision, especially in industries such as aerospace and automotive.

By Application:

Automotive Industry: The automotive sector is a major end-user of machining centers, especially for manufacturing complex parts and components with high precision.

Aerospace Industry: Aerospace manufacturers rely on machining centers for producing intricate components such as turbine blades and engine parts.

Electronics and Consumer Goods: The growing demand for electronics and consumer goods requires high-precision manufacturing, driving the adoption of machining centers.

Medical Devices: The medical device industry is increasingly adopting machining centers for producing components with tight tolerances, such as implants and surgical instruments.

By Region:

North America: The demand for advanced machining centers is strong in the United States and Canada, driven by industries such as aerospace, automotive, and defense.

Europe: Europe is another key region for the machining centers market, with countries like Germany, Italy, and the UK being significant contributors.

Asia-Pacific: The APAC region, particularly China, Japan, and India, is witnessing robust growth due to the increasing industrialization and demand for advanced manufacturing technologies.

The machining centers market is witnessing robust growth driven by technological advancements, increased demand for precision manufacturing, and the adoption of automation. While high initial costs and skilled labor shortages pose challenges, the market is expected to expand in the coming years, driven by demand across various industries. With continued innovations in AI, robotics, and IoT, machining centers are poised to play a key role in the future of manufacturing, offering enhanced precision, efficiency, and productivity.

More Related Reports:

Cleaning Nozzles Market: https://www.marketresearchfuture.com/reports/cleaning-nozzles-market-38779

Airfield Cleaning Equipment Market: https://www.marketresearchfuture.com/reports/airfield-cleaning-equipment-market-39005

Annular Cooler Market: https://www.marketresearchfuture.com/reports/annular-cooler-market-39034

Boring Milling Machine Market: https://www.marketresearchfuture.com/reports/boring-milling-machine-market-39045

Choke Valve Market: https://www.marketresearchfuture.com/reports/choke-valve-market-39095

𝐀𝐛𝐨𝐮𝐭 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐅𝐮𝐭𝐮𝐫𝐞

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research Consulting Services. The MRFR team have a supreme objective to provide the optimum quality market research and intelligence services for our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Market Research Future

Market Research Future

+1 855-661-4441

email us here

Distribution channels: Energy Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release