Infinity Turbine Reveals Waste Heat-Driven ORC Turboshaft with Cavitation Compressor and Magnetic Hydraulic Pump

Infinity Turbine Introduces Waste Heat-Powered Organic Rankine Cycle Turboshaft and Cavitation Compressor Integrated with a Magnetically Geared Hydraulic Pump

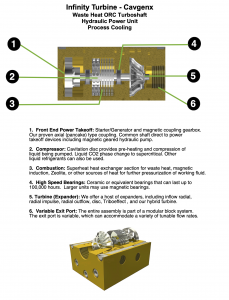

MADISON, WISCONSIN, USA, November 28, 2023 /EINPresswire.com/ -- Infinity Turbine LLC, a trailblazer in renewable energy technology, proudly announces an expansion of its innovative product line: a waste heat-powered Organic Rankine Cycle (ORC) turboshaft, combined with a common shaft cavitation compressor, and now integrated with a magnetically geared and coupled hydraulic pump. This addition signifies a transformative advancement in sustainable energy technology.

Advanced Design and Multifaceted Efficiency

The Infinity Turbine system, already in use with waste-heat-to-power ORC, takes a step further by integrating a common shaft driven cavitation compressor to make a turboshaft cycle, with a magnetically geared hydraulic pump. This pump, designed to convert mechanical energy into hydraulic power efficiently, expands the system's utility and efficiency. They system not only produces shaft horsepower, but also produces cooling as part of its heat pump cycle.

Mobility and Industry Applications

The inclusion of the magnetically geared hydraulic pump and heat pump cycle opens doors to numerous applications:

• Automotive Industry: This technology can power cars with a more sustainable and efficient energy source, reducing reliance on traditional fuels and diminishing environmental impact.

• Construction Sector: Heavy-duty construction equipment can benefit significantly from this system, offering a green solution to energy-intensive operations. Most construction equipment is already hydraulically powered.

• Industrial Machinery: Hydraulic motors for various industrial machines can be powered by this system, enhancing energy efficiency and sustainability in manufacturing processes, while utilizing waste heat to power the process.

• AI Data Center Cooling: The heat pump cycle allows the use of waste heat from heat intensive processors to power its own cooling cycle.

Eco-Friendly, Cost-Effective, and Versatile

In addition to its environmental benefits and cost-effectiveness, the expanded application of Infinity Turbine's system marks a paradigm shift in how industries view and utilize renewable energy. This technology not only leverages waste heat but also transforms it into a powerful tool for various sectors, reinforcing the company's commitment to innovation and sustainability.

A Step Towards a Greener Future

Infinity Turbine's expanded product offering aligns with global sustainability goals, marking a significant contribution to reducing carbon emissions and promoting renewable energy solutions. Infinity Turbine has a rich history in ORC turbine design and thermal processor development since 2008, along with extensive experience in CO2-based technologies since 2004. The Modular Fluid Handling Device, an active patent (US7726331B1), enables the stacking of gas and liquid processing blocks like building blocks to create a turboshaft heat pump cycle. This innovative design allows for the easy addition or modification of stages and functions by simply unbolting a block.

Contact: Greg Giese | CEO | Infinity Turbine LLC | greg@infinityturbine.com | greg@cavgenx.com

Infinity Turbine Website: https://www.infinityturbine.com

Gregory Giese

Infinity Turbine LLC

+1 608-238-6001

email us here

Distribution channels: Automotive Industry, Building & Construction Industry, Energy Industry, Manufacturing, Military Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release